Nhut Nguyen, Senior Design Manager, about the Femernbelt tunnel

Meet one of our senior Design Managers, Nhut Nguyen. Nhut is our Temporary Works Design Manager on world’s longest immersed Tunnel at Femern Link Contractors (FLC).

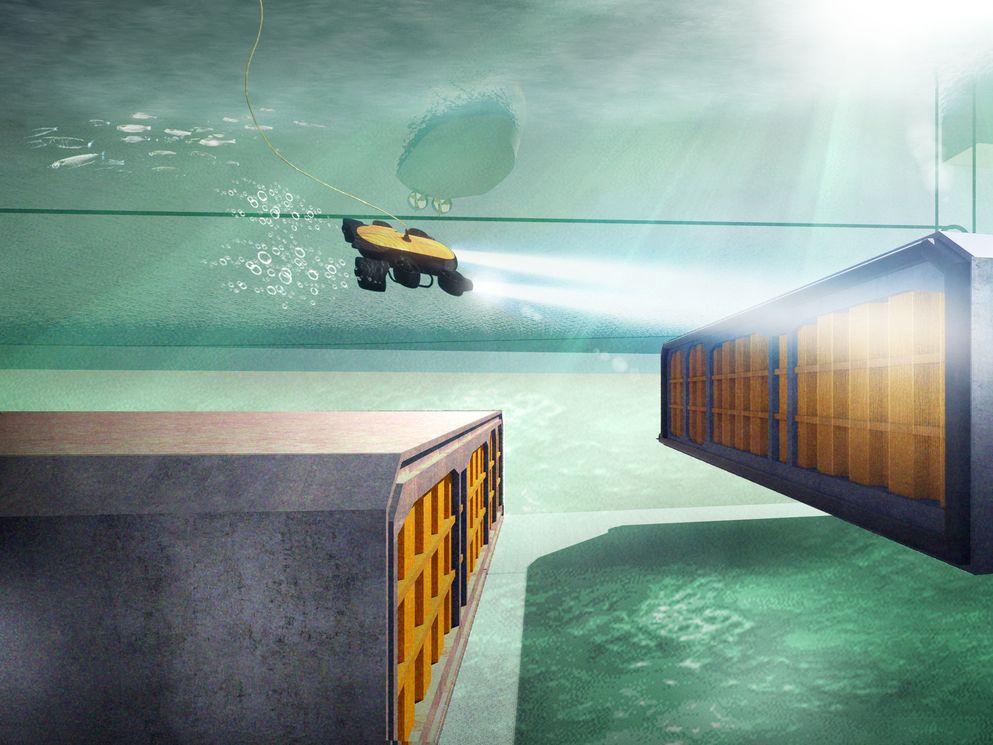

For this mega project, DMC is heavily involved in the design, including a major part of the Temporary Works. BAM, DMC's parent company, is one of the FLC consortium partners constructing the world's longest immersed tunnel. The Fehmarnbelt connection between Denmark and Germany will be an 18-kilometer-long road and rail tunnel. The FLC team is responsible for the design and production of the tunnel elements and their immersion. In this interview, Nhut Nguyen, Temporary Works Design Manager for FLC, shares his roles in the project.

The FLC consortium consists of Vinci Construction Grand Projects (France), Per Aarsleff (Denmark), CFE and DI (DEME, Belgium), Max Boegl (Germany), BAM Infra, and Wayss & Freytag.

Since when have you been involved in the FLC project?

Nhut: 'I have been involved since the exploratory discussions with consortium partners at the beginning of the tender phase in 2013.'

What is your role?

Nhut: 'During the tender phase, I supported the tender team in Denmark remotely with a small team based in our office in Gouda, and I was part of the review team. In 2016, I became the Temporary Works Design Manager for FLC, and I still hold that role. In this role, I coordinate the design of the facilities needed to produce, float, transport over sea, and immerse the tunnel elements. The tunnel elements are prefabricated in six production lines, spread across three massive factory halls. After pouring the concrete, the tunnel elements (each 217 meters long and weighing 80,000 tons) are slid over concrete skidding beams into the basins. These basins are necessary to float the tunnel elements and bring them to sea level. Nearly four kilometers of dikes had to be designed around the basins with a maximum height of up to 20 meters. A floating gate and a sliding gate are required for closure and opening of the basins. The floating gate is a caisson structure over 20 meters high, floated to one of the basin openings and then sunk. The sliding gate is a 100-meter-long and 10-meter-high steel truss door pushed on rails to close the opening before water is pumped into the basin. Harbor and basin facilities are designed for docking of the tunnel elements, ships bringing construction materials, and workboats. Additionally, my teams design the outfitting of the tunnel elements. This includes bulkheads, ballast tanks, tow arrangements, etc. I am also responsible for immersion engineering, involving calculations to float the tunnel elements to their destination in the sea, as well as the computer models and physical model tests needed to study the behavior of the tunnel elements on the waves.'

“Designing a sliding gate comprising a 100-meter-long and 10-meter-high steel truss door pushed on rails takes quite some serious marine expertise”

How is it to work and live internationally?

Nhut: 'One week I work in Denmark, the next week in the Netherlands. My family lives in the Netherlands, so I commute. I work with all consortium partners and also with external consultants. We deal with many different cultures here. It's challenging, but we all share a love for technology, which facilitates collaboration.'

What makes you proud of this project?

Nhut: 'Globally, there are 200 immersed tunnels, with a significant portion in the Netherlands. Dutch expertise is also often utilized in other immersed tunnels worldwide. The Netherlands truly leads globally as the immersed tunnel expert, and BAM has been involved in almost 60 immersed tunnels worldwide over the past 60 years. After the Zuiderzee Works and Delta Works, immersed tunnels are a logical and perfect continuation of the rich Dutch hydraulic engineering history to which BAM contributes significantly.

As a graduate student at TU Delft, I started at DMC in the late '90s. My assignment was related to an immersed tunnel. I have been involved in the design and construction of multiple immersed tunnels, including the two HSL tunnels crossing the Maas and Dordtsche Kil and the New Tyne tunnel in Northeast England. Until a few years ago, the world's longest immersed tunnel was the 6 km BART tunnel (Bay Area Rapid Transit) in San Francisco. A slightly longer tunnel, 6.5 km from Hong Kong to Zhuhai/Macao, surpassed it in recent years. With the Fehmarnbelt tunnel, we are nearly tripling that world record: 18 km, and it's offshore. I am extremely proud to contribute to this mega achievement. Don't underestimate what BAM and DMC are doing here in Denmark together with their joint venture partners; only a few companies worldwide can match this. I hope we retain and continue to develop this knowledge. As a young graduate, I took my first step in this field at DMC with BAM and learned from men who contributed to building the Oosterscheldekering. In the future, I would like to pass on my knowledge and experience to the next generation.

I hope that at the end of this project, we can proudly say that DMC and BAM contributed to a large and successful project, and as a company, we have emerged our knowledge in a positive way. This field is not just a playground for engineers. With the unique expertise we have, there are plenty of opportunities to do business in this niche market.'

Read more on FLC project.